Durable and Efficient Small Conveyor Chain for Your Business Needs

By:Admin

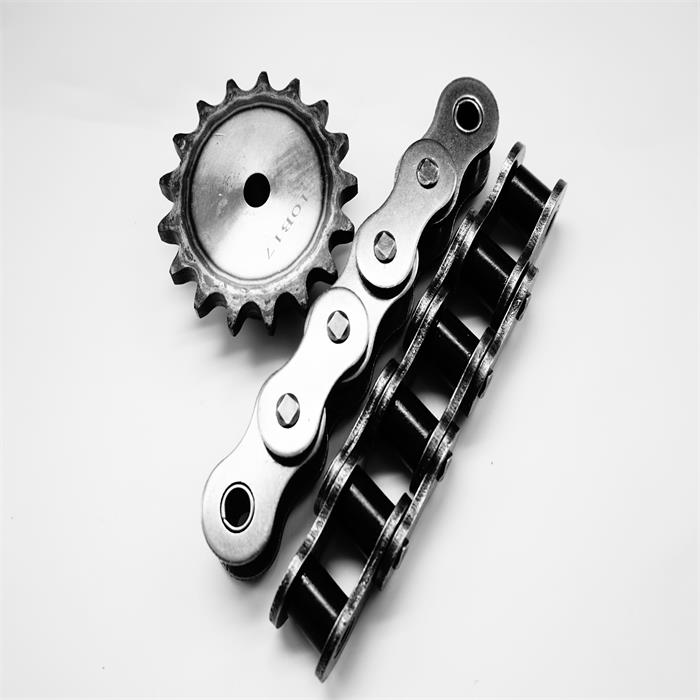

In the fast-paced world of manufacturing and material handling, efficiency and reliability are key factors for success. A small size conveyor chain plays a crucial role in maintaining smooth and efficient material flow within production facilities. From automotive assembly lines to food processing plants, these conveyor chains are an essential component in keeping operations running smoothly.

[Introduction of the Company]

At [Company Name], we are proud to be at the forefront of providing high-quality small size conveyor chains to meet the diverse needs of our customers. With a strong focus on research and development, we have been able to design and manufacture conveyor chains that offer superior performance, durability, and efficiency.

Since our establishment, we have consistently strived to innovate and improve our products to meet the evolving demands of the industry. Our commitment to quality and customer satisfaction has earned us a strong reputation as a reliable partner for businesses looking for dependable conveyor chain solutions.

[Importance of Small Size Conveyor Chains]

Small size conveyor chains are widely used in a variety of industries for transporting a wide range of materials, such as parts, components, and products, from one point to another within a production facility. These chains are essential for ensuring efficient and timely movement of goods, which is crucial for maintaining productivity and meeting deadlines.

The performance of a conveyor chain directly impacts the overall efficiency of a production line. A well-designed and properly maintained chain can significantly reduce downtime, prevent material spillage, and minimize the risk of damage to products. As a result, businesses can achieve higher throughput and lower operating costs, ultimately leading to improved profitability.

[Features and Benefits of Our Small Size Conveyor Chains]

At [Company Name], we offer a range of small size conveyor chains that are engineered to deliver exceptional performance and reliability. Our chains are built to withstand the rigors of heavy-duty industrial applications, and they are designed to operate smoothly and quietly, even under demanding conditions.

Some key features of our small size conveyor chains include:

- High tensile strength: Our chains are made from high-quality materials, ensuring they can handle the stress of heavy loads and continuous operation.

- Precision engineering: Each chain is manufactured with precision to ensure accurate alignment and smooth operation, reducing wear and tear on the system.

- Corrosion resistance: Our chains are designed to withstand exposure to harsh environments, including moisture, chemicals, and extreme temperatures.

- Customization options: We offer a variety of chain configurations and accessories to suit specific application requirements, allowing customers to tailor the conveyor chain to their exact needs.

The benefits of choosing our small size conveyor chains include:

- Improved reliability and uptime

- Enhanced material handling efficiency

- Long service life and reduced maintenance costs

- Compatibility with a wide range of applications

- Support from our knowledgeable and responsive customer service team

[Customer Testimonial]

"We have been using [Company Name]'s small size conveyor chains in our production facility for several years now, and we couldn't be happier with their performance. The chains have been extremely reliable, and they have helped us to streamline our material handling processes. Their team has been a pleasure to work with, and we appreciate their dedication to providing top-notch products and service."

[Conclusion]

In conclusion, small size conveyor chains are a critical component of modern material handling systems, and choosing the right chain can make a significant difference in the efficiency and productivity of a production facility. At [Company Name], we are committed to delivering high-quality conveyor chains that offer superior performance, reliability, and value to our customers. With our extensive experience and expertise in the industry, we are confident in our ability to provide innovative solutions to meet the evolving needs of the market. If you are in need of a reliable conveyor chain solution, we encourage you to reach out to us and learn more about how we can help optimize your material handling processes.

Company News & Blog

How to Connect Chain Links: A Step-by-Step Guide

The global demand for high-quality chain links for various industrial applications has been steadily increasing in recent years. This is due to the growing need for reliable and durable chain links that can withstand the demands of heavy-duty operations in industries such as manufacturing, construction, and agriculture. As a leading producer of premium chain links, {Company Name} has been at the forefront of meeting this demand and providing innovative solutions to customers worldwide.{Company Name} is a renowned manufacturer and supplier of a wide range of chain links, including roller chains, leaf chains, and attachment chains. With over 50 years of experience in the industry, the company has established a strong reputation for delivering top-notch products that meet the highest standards of quality and performance. {Company Name} prides itself on its cutting-edge manufacturing processes and strict quality control measures, ensuring that every chain link produced meets the precise specifications and requirements of its customers.In a recent announcement, {Company Name} revealed that it has seen a significant increase in orders for its chain links from both existing and new customers. This surge in demand can be attributed to the company's unwavering commitment to delivering exceptional products that offer superior durability, strength, and reliability. {Company Name} attributes its success to its continuous investment in research and development, which has allowed it to stay ahead of the curve and develop new and innovative chain link solutions to cater to evolving industry needs.One of the key factors driving the high demand for {Company Name}'s chain links is the increasing focus on efficiency and productivity in industrial operations. The company's chain links are designed to withstand heavy loads, high speeds, and harsh operating conditions, making them the ideal choice for a wide range of applications. From conveyor systems and agricultural machinery to industrial equipment and material handling systems, {Company Name}'s chain links offer unmatched performance and longevity, helping businesses optimize their processes and achieve greater efficiency.Furthermore, {Company Name}'s emphasis on sustainability and environmental responsibility has also resonated with its customers, who are increasingly seeking products that are not only reliable and durable but also environmentally friendly. {Company Name} has implemented sustainable manufacturing practices and is committed to reducing its environmental footprint, making its chain links a preferred choice for companies looking to align with eco-friendly principles.To keep up with the growing demand for its chain links, {Company Name} has ramped up its production capacities and expanded its distribution network to ensure prompt and efficient delivery to its customers worldwide. The company has also continued to invest in its workforce and technology, ensuring that it remains at the forefront of innovation and can readily adapt to the evolving needs of its customers.Looking ahead, {Company Name} remains committed to pushing the boundaries of chain link technology and delivering products that exceed customer expectations. With a strong focus on quality, performance, and sustainability, the company is well-positioned to continue leading the market and setting new standards for excellence in the industry.In conclusion, the increasing demand for high-quality chain links underscores the crucial role they play in various industrial applications. With its unwavering commitment to excellence, sustainability, and innovation, {Company Name} has emerged as a key player in meeting this demand and continues to be a trusted partner for businesses seeking reliable and durable chain link solutions.

Discover the Latest Roller Chain Catalogue for Your Machinery Needs" -> "Find the Best Roller Chain Catalogue for Your Equipment Needs

Introducing New Roller Chain Catalogue: Streamlining Efficiency in Industrial OperationsIn a world driven by technological advancements, industrial operations require efficient and reliable machinery to fuel productivity. One crucial component that plays a significant role in numerous applications is the roller chain. Designed to transmit mechanical power, roller chains find their applications in various industries ranging from automotive to agriculture.Recognizing the growing demand for such essential components, a prominent manufacturer in the field has released their latest roller chain catalogue. This comprehensive catalogue features a wide range of roller chains suitable for diverse industrial applications. With a commitment to quality and precision engineering, the company aims to optimize the performance and efficiency of machinery across different sectors.The newly released roller chain catalogue encompasses an extensive selection of chains suitable for diverse industries and purposes. Featuring different designs, sizes, and specifications, customers can find the perfect roller chain to match their unique requirements. From standard roller chains to corrosion-resistant options and specialty chains, the catalogue offers a range of solutions to meet the needs of different industries.Importantly, the catalogue not only includes traditional roller chains but also introduces advanced technologies for improved functionality. These innovations include self-lubricating chains, which reduce maintenance needs and increase the lifespan of the chain. Furthermore, the catalogue introduces high-strength chains that can handle heavy loads in demanding working conditions without compromising on performance.A major highlight of the roller chain catalogue is its focus on customization. The manufacturer understands that every industrial operation has unique needs, and therefore offers tailored solutions to meet specific requirements. Customers can work closely with the company's expert engineering team to design and develop custom roller chains that align perfectly with their applications.The company behind this roller chain catalogue has built a reputation for delivering superior quality products. With a strong emphasis on precision engineering and rigorous quality control, customers can trust that every roller chain featured in the catalogue meets the highest industry standards. This reliability ensures that industrial operations can function smoothly and efficiently.Additionally, the manufacturer takes pride in their commitment to sustainability. The roller chain selection includes eco-friendly options, which reduce environmental impact without compromising performance. By investing in these responsible solutions, industries can contribute to a greener and more sustainable future.To simplify the purchasing process, the roller chain catalogue provides detailed product descriptions and specifications. Customers can easily navigate through the catalogue to find the exact chain that suits their needs. Furthermore, the company's dedicated customer support team is readily available to address any queries, provide technical assistance, and ensure a seamless buying experience.With the release of this comprehensive roller chain catalogue, the company aims to become the go-to provider for industrial machinery components. The catalogue's wide range of options combined with the company's reputation for quality and commitment to customer satisfaction positions them as a leading player in the industry.In conclusion, the newly released roller chain catalogue offers a one-stop solution for industries seeking to enhance their operational efficiency. With a diverse range of roller chains, including both traditional options and advanced technologies, customers can find the perfect component for their specific applications. By combining quality, customization, and sustainability, the manufacturer aims to empower industrial operations to thrive in today's competitive marketplace.

Mechanical Power Transmission Through Chain Drive: Common Applications in Vehicles and Machines

: The Reliable Mechanism for Smooth Power TransmissionAs technology continues to advance, many machines have been developed to make our daily tasks easier and efficient. These machines create mechanical energy that needs to be transmitted from one place to another.One of the most reliable mechanisms for transmitting power is through the use of drive chains. Drive chains have been used in a wide variety of machines, including bicycles, motorcycles, industrial equipment, and agricultural machinery. They are made from metal components that are linked together in a specific configuration to create a continuous loop.Drive chains are designed to handle high loads and provide smooth power transmission. They are easy to maintain and have a longer lifespan compared to other power transmission systems. Additionally, drive chains produce less noise and do not require any lubrication.One of the advantages of using drive chains is its ability to transfer power over long distances. This makes it ideal for use in machines that require a lot of power to operate, such as mining equipment and agricultural machinery. Drive chains are also cost-effective compared to other power transmission systems.In the automotive industry, drive chains are a crucial component in the operation of motorcycles and bicycles. These machines require a reliable and efficient means of transmitting power from the engine to the wheels. Drive chains are the preferred method of power transmission due to their strength and longevity.Apart from their high durability, drive chains are also designed to withstand harsh environmental conditions. For instance, most drive chains used in agricultural machinery can withstand harsh weather conditions such as high humidity and extreme temperatures.One disadvantage of drive chains is that they require occasional maintenance to ensure they function optimally. Failure to maintain drive chains may cause them to break, which can result in machine downtime and costly repairs. However, maintenance is usually minimal and can be done by anyone with basic mechanical skills.In conclusion, drive chains are an excellent choice for power transmission systems due to their durability, cost-effectiveness, and ability to handle high loads. They are easy to maintain, and their ability to transfer power over long distances makes them the preferred choice for many industries. If you're looking for a reliable means of transmitting power, consider using drive chains.

Revolutionary Machine Chain Technology Transforms Grain Industry

Grain Machine Chain Launches a Revolutionary New Product to Boost Efficiency in Grain HandlingGrain Machine Chain, a leading provider of conveyor systems for the agricultural industry, has launched a revolutionary new product that promises to transform the way grain is handled and stored. The company's latest offering is an innovative chain that is designed to improve efficiency, reduce maintenance costs and minimize downtime.According to the CEO of Grain Machine Chain, the new product is the result of years of research and development efforts. The company's team of engineers and technicians worked closely to identify the key challenges that farmers and grain handlers face in their day-to-day operations. They then set out to develop a solution that would address these challenges and make the process more efficient and streamlined.The new chain is made from high-quality materials and features a robust design that is built to withstand the rigors of the agricultural environment. Its unique construction allows for easy installation and maintenance, as well as significantly reducing wear and tear over time. Additionally, the chain is engineered to provide smooth and reliable operation, ensuring that the grain is transported safely and efficiently throughout the handling system.The launch of this new product comes at a critical time for the agricultural industry. With global demand for food expected to double by 2050, farmers are under increasing pressure to increase their yields and maximize their output. This has led to a growing need for more efficient and effective grain handling systems, which can help to streamline the process and reduce costs.Grain Machine Chain's new product has already generated significant interest among farmers and grain handlers across the country. Many are eager to take advantage of the greater efficiency and reduced downtime that the new chain promises. Grain Machine Chain has established a reputation for providing high-quality products and exceptional customer service, and the launch of this new product is expected to boost the company's market position even further.In addition to its innovative product offerings, Grain Machine Chain is also known for its commitment to sustainability and environmental responsibility. The company has implemented a range of initiatives designed to reduce its carbon footprint and promote greater sustainability in the agricultural industry.For example, the company has invested heavily in the development of new technologies that can help to reduce energy consumption and minimize waste. It has also implemented a range of green practices, such as recycling and responsible waste management, to ensure that its operations are as environmentally friendly as possible.Grain Machine Chain's new product is a testament to the company's ongoing commitment to innovation, sustainability, and customer satisfaction. With its unique design and advanced features, the new chain promises to revolutionize the way that farmers and grain handlers handle and store their products. As global demand for food continues to grow, this new product is sure to play a key role in helping the agricultural industry to meet the challenges of the future.

High Security and Industrial Chain Link Fence Systems in Canada – Supply and Installation Services

IntroductionChain link fences have been a staple in the fencing industry for a long time. They are suitable for both residential and commercial settings due to their durability, affordability, and low-maintenance features. However, chain link fences come in different types based on their application. In this blog post, we will discuss the industrial chain link fence system, its components, benefits, and how to choose the right chain link system for your project.What is an Industrial Chain Link Fence System?An industrial chain link fence system is designed to provide security and protection in industrial settings. Typically, an industrial chain link fence is taller and heavier than a standard residential chain link fence. It is often used in factories, warehouses, manufacturing plants, and other industrial applications where a high level of security is required.Components of Industrial Chain Link Fence SystemThe components of an industrial chain link fence system are similar to those of a standard chain link fence. They include:1. Galvanized steel framework – This includes posts, rails, and fittings. They provide support for the chain link fabric and are often made from galvanized steel, which is corrosion-resistant.2. Chain link fabric – This is the mesh that makes up the fence and provides security. It is made from galvanized steel wire, which is woven together to form a diamond pattern.3. Top rail – This is a horizontal pipe that runs along the top of the fence and provides additional strength and support.4. Tension wire – This is a wire that runs along the bottom and top of the fence to provide additional support and prevent the fence from sagging.Benefits of an Industrial Chain Link Fence1. SecurityThe primary benefit of the industrial chain link fence system is security. These fences provide a visible barrier that deters unauthorized entry and keeps intruders out. They can be customized with additional features for added security, such as barbed wire or razor wire toppings.2. DurabilityIndustrial chain link fences last longer than other types of fencing due to their galvanized steel construction. They are also resistant to weather, corrosion, and rust, making them a suitable choice for outdoor installations.3. Low MaintenanceIndustrial chain link fences require minimal maintenance. They can be easily cleaned with a pressure washer or hose, and any damage can be easily repaired.How to Choose the Right Industrial Chain Link System for Your ProjectWhen choosing an industrial chain link fence system, consider the following factors:1. HeightThe height of the fence should be determined by the level of security required and local zoning regulations. In most cases, industrial chain link fences range from six to twelve feet.2. GaugeThe gauge of the metal wire used for the chain link fabric determines the strength and durability of the fence. A higher gauge indicates a thinner wire and less strength. Selecting the right gauge will depend on the specific application and security needs.3. CoatingThe type of coating on the chain link fabric and framework will determine the fence's corrosion resistance. Galvanized steel provides the most protection against rust and corrosion.ConclusionIndustrial chain link fence systems are essential for providing security and protection in industrial settings. They are durable, low maintenance, and customizable. When choosing a chain link fence system, consider the height, gauge, and coating for the specific application. With these factors in mind, you can choose the perfect industrial chain link fence system for your project.

Discover the Benefits of Using a Double Pitch Roller Chain for Your Industry

Double Pitch Roller Chain Continues to Revolutionize the Industrial and Manufacturing IndustryFor years, industrial and manufacturing companies worldwide have been relying on the traditional roller chain as the standard for their products. While this type of chain has been reliable and served its purpose, its design has not necessarily been the most innovative or efficient. However, in recent years, the Double Pitch Roller Chain has surfaced as a new and improved option for those seeking a more productive and cost-effective solution. With several decades of experience in the manufacturing business, the industry leader introduced the Double Pitch Roller Chain, a product that has since changed the game in terms of quality and performance. While similar products are available on the market, the Double Pitch Roller Chain stands out because of its durability and reliability. Constructed with high-quality materials and manufactured to withstand even the harshest of environments, the Double Pitch Roller Chain has quickly become the go-to option for many industrial companies. This chain is designed with increased flexibility, a longer lifespan, and less maintenance needs than its traditional counterpart. The Double Pitch Roller Chain is an engineering marvel, consisting of high-quality steel and advanced technology. It is a perfect solution for a wide range of industrial applications, including conveyor systems in the food and beverage industry, automotive assembly lines, and even agricultural equipment. What makes the Double Pitch Roller Chain special is its unique design. It is manufactured with a longer pitch than typical roller chains of comparable size, making it more flexible and adaptable to various conditions. The added flexibility means that the chain can bend and move more easily around corners and obstacles, therefore reducing the risk of damage to surrounding equipment.Furthermore, the increased durability of Double Pitch Roller Chain can lengthen its lifespan and require less frequent maintenance. This extra level of endurance cuts down on the frequency of maintenance, freeing up resources and lessening expenses associated with its upkeep.The Double Pitch Roller Chain’s innovative design and exceptional quality have made it an essential component for some of the largest manufacturing companies. It has become the preferred choice in sectors such as agriculture, food and beverage, transportation, and construction.One of the most significant benefits of using Double Pitch Roller Chain is its cost-effectiveness. The durability of this chain combined with the reduction of maintenance costs and energy consumption is of significant advantage for those looking to streamline their production process. Also, this type of chain reduces the likelihood of replacing worn-out parts, which results in reduced production downtime.The Double Pitch Roller Chain is also versatile, customizable and available in various sizes. Companies with unique and specific needs can order custom chain sizes at an affordable cost. The flexibility of this type of chain has broadened its applications beyond standard roller chains; they are now in hydraulic equipment, welding, and other specialties where durability is critical.In summary, the Double Pitch Roller Chain plays a vital role in industries that demand increased efficiency, durability, and cost-effectiveness. This product has a proven track record of improving processes, saving costs, and prolonging the lifespan of machinery. An investment in the Double Pitch Roller Chain is a sound one for any company seeking to stay on the brink of innovation.

Discover the Power and Efficiency of 3/8 Pitch Roller Chain: An Essential Guide

Title: Innovations in 3/8 Pitch Roller Chain Enhance Industrial Efficiency and DurabilityIntroduction:[Company Name], a leading provider of industrial solutions, is revolutionizing the manufacturing sector with their groundbreaking advancements in 3/8 pitch roller chain technology. By combining their expertise in material engineering and precision manufacturing techniques, the company has developed a range of high-performance roller chains that offer enhanced efficiency, durability, and reliability. These innovations are set to transform various industries, including automotive, construction, and agriculture, among others. Let's delve deeper into the key features and benefits of [Company Name]'s cutting-edge 3/8 pitch roller chain.Efficiency through Advanced Design:[Company Name]'s 3/8 pitch roller chain incorporates a meticulously designed structure that maximizes power transmission efficiency. By optimizing the performance of each component, such as the rollers, pins, and plates, the company has been able to reduce friction and energy losses. The reduced friction results in less wear and tear, increasing the overall lifespan of the roller chain. This efficiency improvement also translates into lower maintenance requirements and increased productivity for businesses utilizing the chain in their operations.Superior Durability:One of the notable characteristics of [Company Name]'s 3/8 pitch roller chain is its exceptional durability. The rollers, crafted from high-quality materials, undergo a rigorous heat treatment process, ensuring superior hardness and wear resistance. This attribute significantly reduces the chances of premature chain failure, even in demanding environments characterized by extreme temperature fluctuations, heavy loads, and corrosive elements. The roller chain's ability to withstand such harsh conditions not only provides peace of mind to industrial operators but also translates into substantial cost savings by minimizing downtime and replacement expenses.Precision Engineering for Enhanced Performance:[Company Name] employs state-of-the-art manufacturing technologies, including computer-controlled machining and assembly processes, to ensure precision engineering in every 3/8 pitch roller chain they produce. This meticulous attention to detail results in a roller chain that delivers consistent performance and smoother operation. The precise roller-to-sprocket engagement facilitates improved power transfer, minimizing slippage and maximizing overall efficiency. Consequently, businesses utilizing [Company Name]'s roller chain can optimize their production processes, enhance equipment performance, and ultimately boost their bottom line.Versatility for Various Applications:[Company Name]'s 3/8 pitch roller chain caters to a wide range of applications across multiple industries. Whether it is powering conveyors in the automotive sector, supporting heavy-duty equipment in construction, or driving machinery in agricultural settings, the roller chain proves its versatility and adaptability. The company offers a comprehensive selection of roller chains with varying weight capacities and lengths to suit diverse operational requirements. Additionally, they provide customized solutions to meet specific customer needs, further enhancing the applicability of their products.Commitment to Sustainability:In addition to the numerous performance benefits, [Company Name] also prioritizes sustainability in their roller chain production. They actively embrace eco-friendly manufacturing practices that minimize waste, reduce energy consumption, and employ materials with a lower environmental impact. By creating durable roller chains that require less frequent replacements, the company contributes to a more sustainable industrial landscape, minimizing overall resource consumption and waste generation.Conclusion:[Company Name]'s innovative 3/8 pitch roller chain technology is set to transform industrial operations with its advanced design, superior durability, and precision engineering. These characteristics enable businesses to enhance their efficiency, reduce maintenance costs, and achieve greater productivity. With a commitment to sustainability, [Company Name] ensures that their roller chains not only fulfill the immediate operational needs of industries but also contribute to a greener and more environmentally conscious future. As the demand for optimized industrial performance continues to grow, [Company Name] remains at the forefront, providing reliable solutions that drive progress and success.

C-Type Double Pitch Roller Chain with Delrin Rollers: Features and Benefits

Title: The Power and Reliability of ANSI Standard C-Type Double Pitch Conveyor Roller ChainsIntroduction:In the world of industrial operations and material handling, the importance of reliable and efficient conveyor systems cannot be stressed enough. Key components of these systems are roller chains, which play a significant role in achieving smooth and uninterrupted movement of materials. In this blog, we will explore the features and benefits of ANSI Standard C-Type Double Pitch Roller Chains with Oversized Delrin (Plastic) Rollers. We will also delve into the crucial aspect of keyword inclusion for optimal SEO performance.Section 1: Understanding ANSI Standard C-Type Double Pitch Roller ChainsIn the world of industrial roller chains, ANSI Standard C-Type Double Pitch Roller Chains have earned a reputation for their exceptional performance and durability. These chains are designed with oversized Delrin (Plastic) rollers, which enhance rotation on the bushing, reduce impact loads on the sprocket tooth, and ensure a smoother and more efficient operation. The incorporation of Delrin rollers also helps in minimizing noise and vibration, thus contributing to a quieter working environment.Section 2: Enhanced Strength and Wear ResistanceOne of the standout features of PEER Chain's roller chains is that all their components are heat treated to achieve maximum strength and wear resistance. Heat treatment not only enhances the overall durability of the chain but also allows it to withstand heavy loads and high-speed applications. This ensures that the chain maintains its integrity even in demanding and challenging industrial environments.Section 3: Pre-Loading for Optimal PerformanceAll PEER roller chains, including ANSI Standard C-Type Double Pitch Roller Chains, are pre-loaded during the manufacturing process. Pre-loading involves applying a specific tension to the chain, ensuring it is perfectly aligned and ready for installation. This pre-loading process not only eliminates the possibility of slack in the chain but also helps in extending its overall lifespan. Proper pre-loading also reduces the risk of premature wear, leading to lower maintenance costs and improved operational efficiency.Section 4: Benefits of ANSI Double Pitch Conveyor Roller Chains4.1 Improved Efficiency: The oversized Delrin rollers significantly reduce friction during chain movements, resulting in improved efficiency. This efficient operation leads to optimized conveyor system performance, allowing for increased productivity.4.2 Quicker Installation: With their pre-loaded design and easy alignment, ANSI Double Pitch Conveyor Roller Chains reduce installation time, ensuring faster system setup and reduced downtime.4.3 Noise Reduction: The incorporation of Delrin rollers helps in reducing noise levels and vibrations during operation, creating a more pleasant work environment and reducing employee fatigue.4.4 Enhanced Versatility: ANSI Double Pitch Conveyor Roller Chains are designed to accommodate a wide range of applications and industrial environments. Their high strength and wear resistance make them suitable for demanding industries such as food processing, manufacturing, and agriculture.Section 5: SEO and Keyword InclusionIncorporating keywords into your content is crucial for effective search engine optimization (SEO). For this blog, the targeted keywords are "ANSI Double Pitch Conveyor Roller Chains." Including these relevant keywords throughout the content will ensure that the blog ranks higher in search engine results, making it more visible to potential readers who are searching for information related to this topic.Conclusion:In summary, ANSI Standard C-Type Double Pitch Roller Chains with Oversized Delrin (Plastic) Rollers are a reliable and efficient solution for conveyor systems in various industrial applications. Their superior strength, wear resistance, and optimized performance make them a preferred choice for businesses looking for long-lasting and efficient conveyor systems. By recognizing the importance of keyword inclusion for SEO, we can ensure that this informative blog reaches a wider audience, helping them understand the benefits and applications of ANSI Double Pitch Conveyor Roller Chains.

High Quality Roller Chain Crank Link - Best Supplier in China for Energy Saving Equipment Parts

Are you in need of high-quality roller chain crank links? Look no further! We have found the best supplier in China for all your energy-saving equipment parts needs. Introducing Pengrunjintai.com, the leading provider of roller chain crank links.When it comes to roller chain crank links, it is crucial to invest in products that are up to standard and made of top-notch materials. With Pengrunjintai.com, you can rest assured that their roller chain crank links meet all the necessary specifications. They offer both standard and nonstandard options, catering to the diverse needs of their customers.One of the most crucial aspects of roller chain crank links is their material composition. Pengrunjintai.com understands the importance of durability and reliability, which is why their roller chain crank links are made of high-quality iron. This material ensures that the crank links have excellent tensile strength, capable of withstanding heavy loads and high tension.Located in Zhejiang, China, Pengrunjintai.com is proud to represent the Chinese manufacturing industry and provide customers with top-of-the-line products. Their brand, Shuangjia, is synonymous with quality and trust. When you choose Pengrunjintai.com as your supplier, you are guaranteed to receive roller chain crank links that adhere to the highest manufacturing standards.Pengrunjintai.com offers a wide range of roller chain crank links to suit various applications. Their model numbers vary from 30 to 160, ensuring that you will find the perfect fit for your equipment. Whether you require a smaller size for light-duty applications or a larger size for heavy-duty industrial machinery, Pengrunjintai.com has got you covered.Choosing a reliable supplier is essential when it comes to roller chain crank links. With Pengrunjintai.com, you can rely on their expertise and years of experience as a China supplier. They understand the intricacies of roller chain crank links and deliver products that exceed expectations.When it comes to packaging, Pengrunjintai.com ensures that their roller chain crank links are delivered to you safely and securely. However, if you prefer to have the brand name removed from the packaging, they can accommodate this request. Customer satisfaction is their top priority, and they ensure that every aspect of their products and services is tailor-made to meet your needs.In conclusion, if you are in need of high-quality roller chain crank links, Pengrunjintai.com is the best supplier in China to meet your needs. With their standard and nonstandard options, top-notch iron material, and unbeatable tensile strength, their roller chain crank links will withstand the toughest applications.Located in Zhejiang, China, Pengrunjintai.com proudly represents the Chinese manufacturing industry and ensures that their brand, Shuangjia, offers nothing but the best. With a wide range of model numbers available, you are guaranteed to find the perfect fit for your requirements.Trust Pengrunjintai.com as your supplier and experience the durability and reliability of their roller chain crank links. They understand the importance of customer satisfaction and go above and beyond to ensure that every aspect of their products and services is of the highest quality.Choose Pengrunjintai.com as your supplier for roller chain crank links, and you won't be disappointed. Contact them today to place your order and experience the best roller chain crank links China has to offer.Keywords: High-quality roller chain crank links, China supplier, energy-saving equipment, Pengrunjintai.com, iron material, tensile strength, Zhejiang, Shuangjia, standard and nonstandard options.

Maximizing Efficiency: Discover the Benefits of Chain Driven Rollers

In the world of manufacturing, production efficiency is key, and having the right components can make all the difference. One of the key components in industrial manufacturing is the chain-driven roller. Chain-driven rollers enable items to move along a production line, helping to streamline manufacturing processes and increase production efficiency. One leading manufacturer of chain-driven rollers has emerged as a leader in the industry, providing quality products and unparalleled service to customers around the globe.The company, which prefers to remain unnamed, has been in the business for over 50 years and has established itself as a leader in the field of chain-driven rollers. With precision engineering, cutting edge technology, and a commitment to quality, the company has earned a reputation for excellence in the industry.Their chain-driven rollers are used in a wide range of manufacturing applications, including electronics, automotive, food processing, and packaging. The rollers are designed to provide superior durability and longevity, ensuring that they can withstand the daily wear and tear of even the most demanding manufacturing environments.The company offers a wide range of chain-driven rollers, including heavy-duty rollers, light-duty rollers, and custom rollers to meet the unique needs of each customer. Their heavy-duty rollers are capable of handling loads of up to 2000 pounds, making them ideal for use in heavy manufacturing applications. Their light-duty rollers are designed for more delicate applications, such as in the electronics industry.In addition to their standard rollers, the company also offers custom rollers designed to meet the specific needs of each customer. These custom rollers can be designed in a wide range of sizes, shapes, and configurations to meet the exact requirements of each application.The company's commitment to quality is evident in every aspect of their operations, from their state-of-the-art manufacturing facilities to their exceptional customer service. They use the latest technology to ensure that each roller is manufactured to the highest standards, and they employ a team of highly skilled technicians to ensure that each roller meets strict quality control standards.The company's customer service goes above and beyond, with knowledgeable representatives available to assist customers with everything from product selection to installation. They pride themselves on their ability to provide exceptional service and support, ensuring that their customers are satisfied with their products and their experience.In addition to their commitment to quality and service, the company is also dedicated to sustainability. They have implemented a range of green initiatives in their manufacturing operations, including the use of energy-efficient equipment, the recycling of materials, and the implementation of environmentally friendly processes.Overall, the company's chain-driven rollers are an essential component in many manufacturing applications, and their commitment to quality, service, and sustainability make them a top choice for customers around the world. With over 50 years of experience, the company has established itself as a leader in the industry, providing quality products and exceptional service to customers across a wide range of industries. If you are in need of high-quality chain-driven rollers, look no further than this industry leader.