The Ultimate Guide to Conveyor Chain Drive Systems

By:Admin

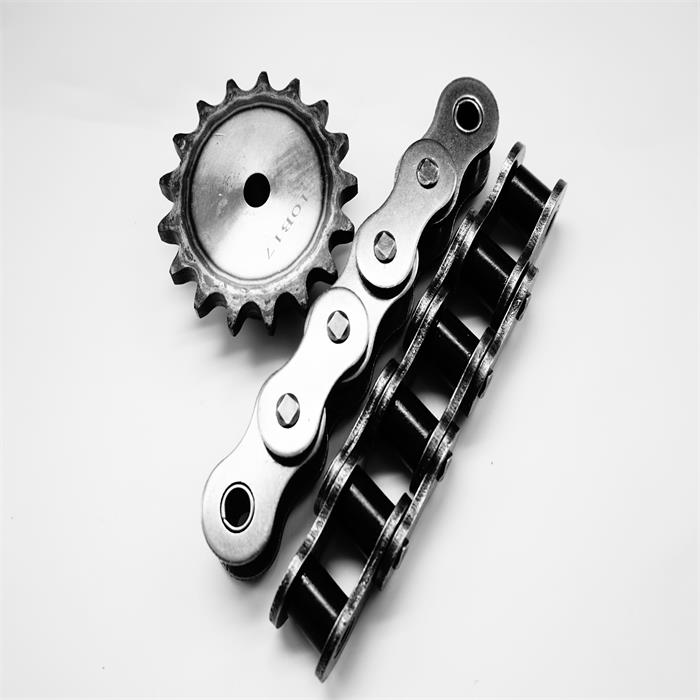

Conveyor chain drives are an essential component in numerous industries, facilitating the movement of heavy loads with ease and efficiency. They are widely used in manufacturing, distribution, and logistics processes, playing a crucial role in enhancing productivity and streamlining operations. As the demand for reliable and high-performance conveyor chain drives continues to grow, companies are constantly innovating and introducing new solutions to meet the evolving needs of the industry.

One such company at the forefront of developing cutting-edge conveyor chain drive solutions is {}. With a rich history dating back to 1951, {} has established itself as a leading manufacturer and supplier of power transmission and conveyor chain products. The company's commitment to delivering innovative and reliable solutions has earned them a solid reputation in the industry.

{} offers a comprehensive range of conveyor chain drives that are designed to meet the diverse needs of industrial applications. From standard roller chains to engineered steel chains, the company's product portfolio is tailored to deliver exceptional performance and durability. With a focus on quality and precision engineering, {} has successfully set itself apart as a preferred choice for businesses seeking superior conveyor chain drive solutions.

In addition to its extensive product offerings, {} takes pride in its ability to provide custom-designed conveyor chain drives to meet specific customer requirements. This flexibility and dedication to meeting unique needs have positioned {} as a trusted partner for businesses across various industries. By leveraging advanced manufacturing technologies and a team of experienced engineers, the company has the capability to develop tailored solutions that optimize operations and enhance overall efficiency.

One of the key factors driving the success of {} is its relentless commitment to research and development. The company continually invests in new technologies and processes to improve the performance and reliability of its conveyor chain drives. By staying at the forefront of innovation, {} has been able to introduce advanced features and enhancements that address the evolving demands of the industry.

Moreover, {} is dedicated to ensuring that its conveyor chain drives adhere to the highest standards of quality and safety. The company complies with rigorous manufacturing processes and quality control measures to guarantee that its products meet or exceed industry regulations and standards. This unwavering dedication to quality assurance has instilled confidence in customers, making {} a trusted and reputable supplier in the market.

As the industrial landscape continues to evolve, the demand for conveyor chain drives that offer increased efficiency, reliability, and longevity is growing. With its proven track record of delivering top-of-the-line products, {} is well-positioned to meet this demand and drive the industry forward. Through ongoing innovation and a customer-centric approach, the company is poised to play a pivotal role in shaping the future of conveyor chain drive solutions.

In conclusion, {} has demonstrated a strong commitment to advancing the capabilities of conveyor chain drives through its dedication to innovation, quality, and customer satisfaction. As the company continues to expand its product offerings and technological capabilities, it is poised to remain a leading force in the industry. With a focus on delivering reliable and high-performance solutions, {} is set to revolutionize industrial productivity and drive the efficiency of businesses across various sectors.

Company News & Blog

High-quality Roller Chain 20B-1R for Reliable Performance

Roller Chain 20B-1R is revolutionizing the industrial machinery industry with its exceptional performance and durability. This high-quality roller chain is manufactured by a leading company that specializes in providing top-notch power transmission products to a wide range of industries. With years of experience and expertise in the field, the company has established itself as a trusted and reliable brand in the global market.The Roller Chain 20B-1R is designed to deliver superior performance in demanding industrial applications. It offers high tensile strength, precision engineering, and resistance to wear and fatigue, making it the ideal choice for heavy-duty machinery and equipment. The chain is constructed using premium quality materials and advanced manufacturing techniques, ensuring exceptional durability and reliability in the most challenging operating conditions.With a focus on innovation and technology, the company has continuously invested in research and development to enhance the performance and efficiency of its products. The Roller Chain 20B-1R is a testament to the company's commitment to delivering cutting-edge solutions that meet the evolving needs of the industry. Its high-precision design and seamless operation make it a preferred choice for businesses looking to optimize their production processes and maximize equipment performance.In addition to its exceptional quality, the Roller Chain 20B-1R is backed by a dedicated team of professionals who are committed to providing unparalleled customer support. The company's technical experts are available to offer guidance and assistance to customers, ensuring seamless integration and operation of the chain within their systems. This level of personalized service sets the company apart from its competitors and has earned it a loyal customer base across the globe.Furthermore, the company's stringent quality control measures guarantee that every Roller Chain 20B-1R meets the highest standards of performance and reliability. Each chain undergoes rigorous testing and inspection processes to ensure compliance with international quality and safety regulations. This commitment to excellence has positioned the company as a preferred supplier for businesses seeking premium-grade power transmission products.The Roller Chain 20B-1R is suitable for a wide range of industrial applications, including conveyor systems, agricultural machinery, construction equipment, and more. Its versatility and adaptability make it a valuable asset for businesses across various sectors, providing the strength and durability required to withstand heavy loads and harsh operating conditions. The chain's low maintenance requirements and long service life contribute to cost savings and operational efficiency for businesses.Looking ahead, the company remains dedicated to driving innovation and delivering next-generation solutions to meet the evolving needs of the industry. Its ongoing investment in research and development, along with its commitment to customer satisfaction, positions it as a leader in the global power transmission market. With a proven track record of excellence and a portfolio of high-performance products, the company is poised to continue its success and make a lasting impact on the industrial machinery sector.In conclusion, the Roller Chain 20B-1R is a testament to the company's dedication to excellence and innovation. Its exceptional quality, durability, and performance make it a preferred choice for businesses seeking reliable power transmission solutions. With a strong focus on customer satisfaction and a commitment to driving technological advancements, the company is poised to remain a leader in the industry for years to come.

Durable and Dependable S32 Roller Chain for Agricultural Use

Roller ChainIf you are in the agricultural industry, you know how important it is to have reliable equipment that can withstand the demands of your daily operations. One of the most critical components of any farming equipment is the roller chain.Roller chains are simple but incredibly crucial devices in your agricultural machinery. They transmit power between two rotating shafts, helping run the equipment and keep your farm running smoothly. However, not all roller chains are created equal. That's why you need a high-quality agricultural chain like the S32 roller chain.The S32 roller chain is a high-quality piece of equipment that is designed specifically for agricultural use. It is manufactured out of high-quality components, ensuring strength, durability, and dependability. This roller chain is perfect for use in any agricultural application, from farm machinery to processing equipment.One of the most significant advantages of the S32 roller chain is that it is highly resistant to wear and tear. This means that it can withstand heavy use, frequent exposure to the elements, and other challenges commonly found in the agriculture sector. With this roller chain, you can rest assured that your equipment will run smoothly, avoiding unexpected downtime and costly repairs.The S32 roller chain is also versatile, meaning that it is compatible with most agricultural equipment in use today. Whether you're using new or older equipment, this roller chain can fit seamlessly, making upgrades and replacements much easier.Besides durability and compatibility, the S32 roller chain is also effortless to install. This makes it a great choice for farmers and technicians who want to get back to work as soon as possible. With this roller chain, you don't have to worry about complicated installation processes or needing specialized equipment to handle the job.Overall, the S32 roller chain is a reliable and sturdy agricultural chain that can help keep your farm equipment running as long as possible. With its robustness, versatility, and ease of use, this roller chain is an excellent investment for any farm or agricultural operation.In conclusion, if you are looking for a high-quality roller chain for your agricultural operations, consider investing in the S32 roller chain. Its durability, compatibility, and ease of installation make it a reliable and practical choice for anyone in the agriculture sector. Plus, with its resistance to wear and tear, this roller chain can help you avoid unexpected downtime and costly repairs, ensuring that your equipment runs smoothly no matter the challenges you face.

Roller Chains for Transport and Placement: Your Guide to Conveyor Chains

article on conveyor chains and their various applications.Conveyor chains have become an integral part of the manufacturing and logistics industries. These chains perform the crucial task of transporting and placing goods/products from one location to another. The modern conveyor chains are developed to work flawlessly even in harsh environments while maintaining high efficiency and reliability.A conveyor chain comprises a series of interconnected links that run over sprockets placed at specific distances along the conveyor line. The chains can be classified into several types based on their design and roller systems, such as standard chains, hollow pin chains, and double pitch chains. These chains are widely used in various industries, including automotive, food and beverage, packaging, healthcare, and logistics.The roller chains on the conveyor system are an important component for its efficiency and durability. These chains are usually made of high-quality steel or stainless steel, ensuring high strength, toughness, and resistance to corrosion. To further enhance the performance of conveyor chains, various coatings and surface treatments are applied to these chains as part of the manufacturing process.Conveyor chains have several benefits over other transportation methods. They are highly efficient and can transport goods quickly and smoothly. The chains can handle heavy loads, and the placement of carriers or pins can be adjusted according to the size and shape of the products, making the system versatile and suitable for a wide range of industries. With conveyor systems, the risk of human error and accidents is decreased, thus improving safety in the workplace.The most common application of conveyor chains is in the transportation of goods within a manufacturing facility. They are widely used in assembly lines and production processes to move parts, components, and finished products from one station to another. Conveyor chains are also commonly utilized in logistics and supply chain operations, such as warehousing and distribution centers, to move goods from trucks to storage or packing areas.Another application of conveyor chains is in the food and beverage industry. These chains are designed to handle food products carefully and hygienically, without compromising their quality and safety. The chains are often coated with food-grade materials, such as stainless steel or plastic, and also feature various cleaning mechanisms to ensure that they remain free of contaminants.The healthcare industry also benefits from the use of conveyor chains. They are used in hospitals and medical facilities to transport medical equipment, supplies, and even patients. Conveyor chains designed for medical applications require special coatings and materials that meet hygienic standards and are resistant to disinfectants and chemicals.In conclusion, conveyor chains are an indispensable part of many industries, providing efficient and reliable transportation of goods and products. They are designed to meet the specific needs and requirements of each industry, from manufacturing to healthcare. With the latest technology and advancements in material science, conveyor chains are continually evolving and improving, providing even more benefits and advantages for the businesses that rely on them.

Key Facts about Transmission Roller Chains You Need to Know

Transmission Roller Chain, the leading manufacturer in the industry, is making waves with their innovative and high-quality products. With a history of excellence and a commitment to providing the best solutions for their customers, Transmission Roller Chain is a name that has become synonymous with reliability and performance.Established in 1983, Transmission Roller Chain has been at the forefront of the roller chain manufacturing industry for over three decades. With state-of-the-art facilities and a team of highly skilled engineers and technicians, the company has consistently delivered top-notch products that exceed industry standards. Transmission Roller Chain's commitment to quality and innovation has earned them a strong reputation as a trusted and reliable partner for businesses across a wide range of industries.One of the key factors that set Transmission Roller Chain apart from their competitors is their dedication to research and development. The company is constantly investing in new technologies and processes to improve the performance and durability of their products. This commitment to innovation has resulted in a range of high-performance transmission roller chains that meet the unique needs of their diverse customer base.The company's extensive product line includes a wide range of transmission roller chains, from standard chains to specialty chains designed for specific applications. Whether it's for industrial machinery, agricultural equipment, or automotive applications, Transmission Roller Chain has a solution that meets the most demanding requirements. Their products are known for their durability, reliability, and high performance, making them the top choice for businesses looking for quality transmission roller chains.In addition to their exceptional products, Transmission Roller Chain is also known for their exceptional customer service. The company has a team of knowledgeable and experienced professionals who are dedicated to providing the best possible support for their customers. From product selection to installation and maintenance, Transmission Roller Chain's team is committed to ensuring that their customers have a seamless and positive experience with their products.Furthermore, Transmission Roller Chain is also environmentally conscious and has implemented sustainable manufacturing practices to minimize their impact on the environment. Their commitment to sustainability is evident in their production processes, which are designed to reduce waste and energy consumption. This focus on environmental responsibility has earned Transmission Roller Chain recognition as a company that is committed to making a positive impact on the planet.Looking to the future, Transmission Roller Chain is poised to continue their legacy of excellence by further expanding their product line and developing new technologies. With a solid foundation of experience, expertise, and a commitment to innovation, the company is well-positioned to meet the evolving needs of their customers and the industry as a whole.In conclusion, Transmission Roller Chain is a company that has set the bar high in the transmission roller chain manufacturing industry. With a strong emphasis on quality, innovation, and customer service, the company has earned a reputation as a trusted and reliable partner for businesses across a wide range of industries. As they continue to grow and evolve, Transmission Roller Chain is well-equipped to maintain their position as a leader in the industry and continue to deliver high-quality products that meet the diverse needs of their customers.

C-Type Double Pitch Roller Chain with Delrin Rollers: Features and Benefits

Title: The Power and Reliability of ANSI Standard C-Type Double Pitch Conveyor Roller ChainsIntroduction:In the world of industrial operations and material handling, the importance of reliable and efficient conveyor systems cannot be stressed enough. Key components of these systems are roller chains, which play a significant role in achieving smooth and uninterrupted movement of materials. In this blog, we will explore the features and benefits of ANSI Standard C-Type Double Pitch Roller Chains with Oversized Delrin (Plastic) Rollers. We will also delve into the crucial aspect of keyword inclusion for optimal SEO performance.Section 1: Understanding ANSI Standard C-Type Double Pitch Roller ChainsIn the world of industrial roller chains, ANSI Standard C-Type Double Pitch Roller Chains have earned a reputation for their exceptional performance and durability. These chains are designed with oversized Delrin (Plastic) rollers, which enhance rotation on the bushing, reduce impact loads on the sprocket tooth, and ensure a smoother and more efficient operation. The incorporation of Delrin rollers also helps in minimizing noise and vibration, thus contributing to a quieter working environment.Section 2: Enhanced Strength and Wear ResistanceOne of the standout features of PEER Chain's roller chains is that all their components are heat treated to achieve maximum strength and wear resistance. Heat treatment not only enhances the overall durability of the chain but also allows it to withstand heavy loads and high-speed applications. This ensures that the chain maintains its integrity even in demanding and challenging industrial environments.Section 3: Pre-Loading for Optimal PerformanceAll PEER roller chains, including ANSI Standard C-Type Double Pitch Roller Chains, are pre-loaded during the manufacturing process. Pre-loading involves applying a specific tension to the chain, ensuring it is perfectly aligned and ready for installation. This pre-loading process not only eliminates the possibility of slack in the chain but also helps in extending its overall lifespan. Proper pre-loading also reduces the risk of premature wear, leading to lower maintenance costs and improved operational efficiency.Section 4: Benefits of ANSI Double Pitch Conveyor Roller Chains4.1 Improved Efficiency: The oversized Delrin rollers significantly reduce friction during chain movements, resulting in improved efficiency. This efficient operation leads to optimized conveyor system performance, allowing for increased productivity.4.2 Quicker Installation: With their pre-loaded design and easy alignment, ANSI Double Pitch Conveyor Roller Chains reduce installation time, ensuring faster system setup and reduced downtime.4.3 Noise Reduction: The incorporation of Delrin rollers helps in reducing noise levels and vibrations during operation, creating a more pleasant work environment and reducing employee fatigue.4.4 Enhanced Versatility: ANSI Double Pitch Conveyor Roller Chains are designed to accommodate a wide range of applications and industrial environments. Their high strength and wear resistance make them suitable for demanding industries such as food processing, manufacturing, and agriculture.Section 5: SEO and Keyword InclusionIncorporating keywords into your content is crucial for effective search engine optimization (SEO). For this blog, the targeted keywords are "ANSI Double Pitch Conveyor Roller Chains." Including these relevant keywords throughout the content will ensure that the blog ranks higher in search engine results, making it more visible to potential readers who are searching for information related to this topic.Conclusion:In summary, ANSI Standard C-Type Double Pitch Roller Chains with Oversized Delrin (Plastic) Rollers are a reliable and efficient solution for conveyor systems in various industrial applications. Their superior strength, wear resistance, and optimized performance make them a preferred choice for businesses looking for long-lasting and efficient conveyor systems. By recognizing the importance of keyword inclusion for SEO, we can ensure that this informative blog reaches a wider audience, helping them understand the benefits and applications of ANSI Double Pitch Conveyor Roller Chains.

High-Quality Paver Chain: The Top Choice for Pavement Maintenance

Paver Chain, A Leading Provider of Quality Paving Equipment and SolutionsPaver Chain is a renowned company in the construction and paving industry, providing top-notch paving equipment and solutions to customers worldwide. With a strong reputation for excellence, innovation, and customer satisfaction, Paver Chain has become a trusted partner for contractors, builders, and developers looking to achieve exceptional results in their paving projects.Established in [year], Paver Chain has quickly risen to prominence as a leader in the field, thanks to its commitment to delivering high-quality products and comprehensive support services. The company offers an extensive range of paving equipment, including [list of products], designed to meet the diverse needs of construction projects of all sizes and scales. From asphalt and concrete pavers to screeds, rollers, and material transfer vehicles, Paver Chain's product line is well-equipped to tackle any paving challenge with precision and efficiency.In addition to its cutting-edge equipment offerings, Paver Chain takes pride in its team of industry experts who are dedicated to providing clients with personalized solutions that address their specific requirements. The company's highly skilled engineers and technicians work closely with customers to understand their project goals and offer tailored recommendations that optimize performance and maximize value. Whether it's selecting the right equipment for a particular job or customizing solutions to overcome unique obstacles, Paver Chain's team is committed to supporting clients every step of the way.Moreover, Paver Chain's commitment to quality extends beyond its products and services to encompass environmental and sustainability considerations. The company is steadfast in its efforts to develop eco-friendly paving solutions that minimize the impact on the environment while delivering superior results. By integrating innovative technologies and materials into its equipment, Paver Chain strives to help clients achieve their construction objectives while upholding responsible environmental practices.As a customer-centric organization, Paver Chain places great emphasis on fostering strong relationships with its clients, built on mutual trust, integrity, and reliability. The company's dedication to exceeding customer expectations is exemplified through its responsive support network, accessible technical expertise, and ongoing commitment to delivering value throughout the project lifecycle. Whether it's through on-site training, maintenance services, or timely customer assistance, Paver Chain ensures that its clients are equipped with the knowledge and resources they need to succeed in their paving endeavors.Looking ahead, Paver Chain is poised to continue its growth trajectory and expand its reach in the global market, while maintaining its focus on delivering exceptional products and services. The company remains at the forefront of paving industry trends and advancements, continuously innovating to meet evolving customer needs and stay ahead of the competition. With a solid track record of success and a forward-looking approach, Paver Chain is well-positioned to remain a go-to partner for paving excellence in the years to come.In conclusion, Paver Chain stands out as a trusted provider of high-quality paving equipment and solutions, backed by a commitment to excellence, innovation, and customer satisfaction. With its comprehensive product line, experienced team, and dedication to environmental responsibility, Paver Chain offers customers the assurance of superior performance and value in their paving projects. As the company continues to expand its global presence and advance its offerings, Paver Chain remains a leading force in the construction and paving industry, poised to shape the future of infrastructure development.

35 Roller Chain: An Essential Guide to Understanding and Choosing the Right Size

In the manufacturing industry, there is a high demand for durable and reliable chains that can be used for a wide range of applications. One such chain is the 35 Roller Chain, which has become a staple in the industry due to its quality and performance. This chain, which has been manufactured by a leading company in the industry, has gained a reputation for being one of the most efficient and durable chains available on the market.The 35 Roller Chain is a type of roller chain that is widely used in various industries, including agriculture, construction, mining, and manufacturing. It is designed to operate in high-torque and high-speed conditions and is capable of transmitting power from one mechanism to another.The chain has a pitch of 3/8 inches and is made up of interconnecting roller link plates and pin link plates. The roller link plates are fitted with bushings and rollers that help reduce friction and wear between the plates. This design allows the chain to run smoothly, even under heavy loads and high speeds.The company that produces the 35 Roller Chain is committed to delivering high-quality products that meet the needs and demands of their customers. They have invested heavily in research and development to improve the design and functionality of their chains. This has resulted in the production of a superior chain that is widely used in various industries.One of the key features of the 35 Roller Chain is its durability. The chain is made from high-quality materials that are resistant to wear and corrosion. This makes it ideal for use in harsh environments, where other chains may fail. Additionally, the chain is precision engineered to withstand high loads and pressures, making it a reliable choice for heavy-duty applications.Moreover, the 35 Roller Chain is easy to install and maintain, ensuring that downtime is kept to a minimum. The company provides comprehensive product support, including installation instructions and maintenance manuals, to help customers get the most out of their chains. This ensures that the chains are installed correctly and are maintained properly throughout their lifespan.The 35 Roller Chain is also highly customizable, which means that it can be designed to meet the specific needs of different applications. The company provides a range of customization options, including different chain lengths, custom attachments, and specialized coatings. This allows customers to tailor the chain to meet their exact requirements, ensuring that it performs to the highest standards.In conclusion, the 35 Roller Chain has become a top choice in the manufacturing industry due to its quality, performance, and reliability. The chain has a proven track record of withstanding the toughest conditions, making it an ideal choice for a wide range of applications. With its durability, ease of installation and maintenance, and customizable options, the 35 Roller Chain is a valuable addition to any manufacturing process. The company behind the chain is committed to providing high-quality products and excellent service to their customers, ensuring that they continue to be a leader in the industry.

Newest Innovation in Chain Technology: Hollow Pin Chains Improving Efficiency and Durability" can be re-written as "Revolutionary Hollow Pin Chains: Boosting Efficiency and Longevity in Chain Technology".

Title: The Innovation of Hollow Pin Chain Revolutionizes Industrial ManufacturingIntroduction:In the world of industrial manufacturing, the constant pursuit of efficiency and reliability is paramount. The introduction of the groundbreaking Hollow Pin Chain by a leading industry player has brought about a significant disruption, promising to revolutionize various manufacturing processes. This article explores the features, benefits, and potential applications of the Hollow Pin Chain, highlighting how it is poised to transform the industry.The Hollow Pin Chain: Redefining Industrial Manufacturing:{Company Name}, a trailblazer in industrial manufacturing solutions, continues to demonstrate its commitment to innovation with the introduction of the Hollow Pin Chain. This groundbreaking chain features a unique design that sets it apart from traditional chains as it incorporates hollow pins, which provide numerous advantages for a wide range of applications.Key Features and Benefits:The Hollow Pin Chain's design enhancements deliver a host of benefits that have already captured the attention of industry professionals. One of the key advantages lies in its lightweight construction, allowing for increased speed and reduced energy consumption during operation. This not only streamlines production processes but also contributes to significant cost savings for companies operating on a large scale.Additionally, the hollow pins allow for effortless lubrication. This design feature enables easier access to critical lubrication points, reducing maintenance requirements and prolonging the lifespan of the chain. With enhanced lubrication capabilities, the Hollow Pin Chain greatly minimizes the risks associated with wear and tear, ensuring optimal performance over extended periods.Applications Across Multiple Industries:The versatility of the Hollow Pin Chain makes it applicable to a diverse range of industries. Its lightweight construction and smooth operation make it particularly well-suited for applications in conveyor systems, packaging machinery, food processing, and automotive manufacturing. Additionally, the easy lubrication feature of the Hollow Pin Chain makes it ideal for use in environments where regular maintenance may be challenging, such as industrial ovens or high-temperature areas.In the automotive industry, the Hollow Pin Chain finds a unique application in the manufacturing of transmission systems. Its lightweight design and improved efficiency make it a desirable choice for enhancing the overall performance and durability of vehicles.Moreover, the food processing industry can benefit immensely from the sanitary advantages of the Hollow Pin Chain. The easily accessible hollow pins enable quick cleaning and prevent any residue buildup, ensuring compliance with strict hygiene regulations while maintaining high production speeds.{Company Name}: Pioneering Industrial Innovations:For decades, {Company Name} has consistently been at the forefront of revolutionizing industrial manufacturing processes. The introduction of the Hollow Pin Chain builds on their legacy of excellence, with its exceptional design and numerous benefits. Recognized for its commitment to quality and customer satisfaction, {Company Name} continues to provide cutting-edge solutions that meet the evolving needs of global industries.Conclusion:The advent of the Hollow Pin Chain represents a significant leap forward in industrial manufacturing solutions. With its lightweight construction, improved efficiency, and easy maintenance, this innovative chain has the potential to transform various industries. By simplifying complex processes, reducing energy consumption, and enhancing reliability, the Hollow Pin Chain by {Company Name} ensures a brighter, more efficient future for the manufacturing sector.

Understanding the Benefits of Double Pitch Chain C2042 for Your Business

Double Pitch Chain C2042{Company Name} is proud to announce the launch of its new product, the Double Pitch Chain C2042. As a leading manufacturer of industrial chains, {Company Name} strives to provide high-quality products that meet the needs of its customers. The introduction of the Double Pitch Chain C2042 is a testament to {Company Name}'s commitment to innovation and excellence in the industry.The Double Pitch Chain C2042 is a durable and reliable chain that is designed for a wide range of industrial applications. It is made from high-quality materials and manufactured with precision to ensure its performance and longevity. The chain is suitable for use in conveyor systems, packaging equipment, and other machinery that requires a strong and dependable chain.One of the key features of the Double Pitch Chain C2042 is its double pitch design, which provides increased strength and stability compared to standard chains. This makes it an ideal choice for applications that require a higher level of performance and durability. Additionally, the chain is available in various sizes and configurations to meet the specific needs of different industries and applications.{Company Name} has a long history of providing industry-leading chains and other products to its customers. With a focus on quality and reliability, {Company Name} has established itself as a trusted partner for businesses in a wide range of industries. The introduction of the Double Pitch Chain C2042 further solidifies the company's reputation as a leading provider of industrial chains and related products.In addition to the Double Pitch Chain C2042, {Company Name} offers a comprehensive range of chains and accessories to meet the diverse needs of its customers. This includes roller chains, conveyor chains, attachment chains, and specialty chains for specific applications. With an extensive product line and a commitment to customer satisfaction, {Company Name} is well-positioned to meet the evolving needs of the industrial sector.Furthermore, {Company Name} places a strong emphasis on research and development to continuously improve its products and stay ahead of industry trends. The introduction of the Double Pitch Chain C2042 is the result of extensive research and testing, ensuring that it meets the highest standards of quality and performance. This commitment to innovation and excellence sets {Company Name} apart as a leader in the industry.As part of its dedication to customer service, {Company Name} provides comprehensive support and assistance to help customers find the right chain for their specific needs. The company's team of experts is available to offer technical guidance, product recommendations, and customized solutions to ensure that customers can find the right chain for their application.{Company Name} is excited to introduce the Double Pitch Chain C2042 to its customers and looks forward to the positive impact it will have on their operations. With its outstanding performance and durability, the Double Pitch Chain C2042 is set to become a valuable asset for businesses in various industries. Customers can trust {Company Name} to provide them with reliable and high-quality chains that meet their unique requirements.In conclusion, the introduction of the Double Pitch Chain C2042 is a significant milestone for {Company Name} as it continues to deliver innovative and reliable products to its customers. With its focus on quality, performance, and customer satisfaction, {Company Name} is well-positioned to meet the needs of the industrial sector and maintain its position as a leader in the industry. The Double Pitch Chain C2042 is a testament to {Company Name}'s commitment to excellence and its ability to provide superior solutions for its customers' requirements.

Latest Updates on Sugar Mills: A Detailed Report on the Sugar Industry

Title: Maximizing Efficiency and Productivity in the Sugar Mill IndustryIntroduction:In the thriving sugar mill industry, the key to success lies in optimizing operations, enhancing productivity, and minimizing downtime. A crucial element in facilitating these objectives is the utilization of advanced technology and incorporating efficient practices throughout the supply chain. In this blog, we delve into the critical role of the sugar mill chain and explore ways to enhance its performance, thereby driving the growth of sugar mills.1. Understanding the Sugar Mill Chain:The sugar mill chain is a vital component of the sugar production process. It encompasses various elements, including conveyors, rollers, shredders, centrifuges, and boilers. These components work in harmony to ensure the seamless operation of a sugar mill, from receiving sugarcane to refining it into the final product.2. Key Challenges in Sugar Mill Operations:Efficient sugar mill operations require overcoming several challenges, including reducing costs, increasing throughput, minimizing maintenance efforts, and ensuring the longevity of equipment. By addressing these issues, sugar mills can significantly improve their bottom line.3. Implementing Technological Advancements:One of the most effective ways to optimize sugar mill operations is by embracing automation and digitalization. Smart technologies, such as Internet of Things (IoT) devices, real-time monitoring systems, and advanced analytics, enable proactive maintenance, early issue detection, and optimization of production processes. By leveraging such tools, sugar mills can enhance operational efficiency, reduce breakdowns, and improve overall productivity.4. Enhancing Chain Performance:To streamline the sugar mill chain and maximize productivity, sugar mills should focus on the following aspects: a. Chain Care and Maintenance: Regular inspections and proper lubrication of the sugar mill chain are essential to prevent premature wear and tear. Implementing a proactive chain maintenance schedule minimizes the risk of unexpected breakdowns and ensures consistent performance. b. Chain Selection: Choosing the right sugar mill chain is crucial for efficient operations. Aspects to consider include chain material, design, strength, and resistance to corrosion and abrasion. Working closely with reputable suppliers can help in making informed decisions. c. Chain Alignment and Tension: Proper chain alignment and tension are critical for smooth and reliable operation. Deviations in alignment and incorrect tension may result in premature wear, increased energy consumption, and potential chain failures. Regular audits should be conducted to ensure optimal alignment and tension. d. Chain Lubrication: Adequate lubrication is imperative to prevent corrosion and reduce friction. Regularly lubricating the sugar mill chain using suitable lubricants helps in extending its lifespan and maintaining its performance. e. Chain Inspection and Replacement: Regular inspection and replacement of worn-out or damaged chain components are essential to avoid breakdowns and ensure a continuous production cycle. Timely replacement of weak links in the chain minimizes the risk of chain failure during operation.5. Investing in Workforce Training:Another critical aspect of optimizing sugar mill chain performance is investing in comprehensive training programs for mill operators and maintenance technicians. Equipping the workforce with the necessary skills and knowledge to operate and maintain the chain efficiently reduces downtime, enhances troubleshooting capabilities, and improves overall productivity.6. Collaborating with Supply Chain Partners:Effective collaboration with suppliers, service providers, and industry organizations promotes knowledge-sharing, staying updated with industry best practices, and accessing new technologies. Partnering with reliable and experienced vendors ensures a steady supply of high-quality chain components and reduces lead times, enabling uninterrupted operations.Conclusion:In conclusion, the sugar mill chain plays a pivotal role in the efficient functioning of sugar mills. By prioritizing chain care and maintenance, selecting the right components, and embracing technological advancements, sugar mills can significantly enhance productivity, reduce downtime, and amplify their bottom line. Continuous investment in employee training and working collaboratively with supply chain partners are essential for sustained improvement and success in this dynamic industry. By implementing these measures, sugar mills can thrive in an increasingly competitive landscape, ensuring a sweet future for the industry.